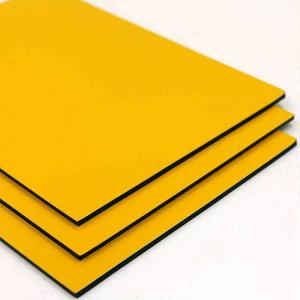

High Gloss Aluminum Composite Panel

White aluminium composite panel or aluminum-plastic panel is a kind of composite new material which has been through surface treatment and a series of technological processing. It's composed of aluminum panels with coating as the surface and PVC plastic panel as the core layer. As the composite panel is composed of two kinds of completely different material, that is, metals and non-metallic, the main characteristics of the original material have been reserved, while the disadvantages of that have been avoided. Thus, it has got many excellent properties, such as luxurious beauty, colorful decoration; Weather resistance, corrosion resistance, anti-strike, fire prevention, moisture proof, sound insulation, heat insulation and shock resistance; Light, easy to process, easy to handle, easy to install, and so on. These properties have opened up a wide application prospect for the black aluminum composite panel.

High gloss aluminum composite panel is a new kind of decoration materials springing up in recent years. The "high gloss" is a kind of processing to improve the gloss of panel surface paint. And the gloss of composite panel surface can be divided into several degrees. The most commonly used gloss bands are matte, flat, bright, highlight, etc. For example, matte means the gloss panel is between 20 and 30 degrees, light is between 60 and 70. And the high gloss is between 85-95, which can clearly visualize things. The processing of high gloss composite panel is relatively simple. It's strongly fireproofing and generally, do not fade for more than 20 years. So that if you choose it, you just need to clean it with clean water and neutral detergent and it will be as shiny as a new one. All these virtues make it widely used in the indoor decoration and the outside adorn of buildings. So how about the price of high gloss aluminum composite panel? And how to distinguish the advantages and disadvantages of the aluminum composite panel?

How about the price of the high gloss aluminum composite panel:

Usually, the coating of the aluminum composite panel used in outer wall is fluorocarbon coating. Because the Fluorocarbon aluminum composite panel is generally suitable for outer use, while the PE aluminum composite panel is suitable for indoor use. The outer wall Fluorocarbon aluminum composite panel is a kind of commonly used curtain wall material, for which its quote is relatively transparent, about CNY 380-450. Of course, the price of ACP varies in the different brand. Generally speaking, the quote of famous brands will be relatively higher because of the superior quality of their products and services.

How to distinguish the advantages and disadvantages of the aluminum composite panel:

1. To observe if the surface of the aluminum composite panel is flat with your eyes and whether there are ripples, bubbles or scratches.2. Measure the thickness of the aluminum composite panel to see whether it reaches the national production requirements, that is, the inner wall plate needs to be thicker than 3mm, the outer wallboard thicker than 4mm, and the thickness of aluminum is necessary to reach 0.5mm.3. Fold the corner of the aluminum composite panel with your hand to see if it is cracked. If the panel can be easily broken off, it's probably made of Residual plastic with slag. Otherwise, the core material is PE.4. To burn the core of the plastic plate which is broken off with fire, the real PE material will be completely burned; the material which is incompletely burned has impurities, which means it is an adulterated material.5. Use the carpenter's thing to open the groove and see whether the front is cracked when bending. If it's cracked, apparently it's made of a defective material, otherwise, it's made of PE material.6. Use the chemical raw material. Use butanone to test whether the coating of outer wall panel is fluorocarbon coating; use the xylene to test the coating of the inner wall panel. Wipe the reagent after five minutes to see if it is dissolved.7. Ask for the quality inspection report, the quality certificate and the national quality certificate from the manufacturer to see if the manufacturer meets the industrial and national standard.Through these methods, you can briefly distinguish the quality of the aluminum composite panel. The excellent aluminum composite panel is much more expensive than the defective goods, while its high quality can be assured. When purchasing aluminum composite panel, you'd better choose the manufacturers who meet the industrial and national standards.The aluminum plastic composite plate is a composite material composed of polyethylene plastic(the core layer) and coated aluminum panel(the surface layer) which has been through chemical treatment. The natural and unique properties of aluminum composite panel determine its wide application: it can be used in building exterior wall, curtain wall plate, old building renovation, interior wall and ceiling decoration, advertising signs, display stand, purify dust prevention engineering. Aluminum plastic composite board has been widely used in China, coming to be a new type of building decoration material.The aluminum plastic composite panel is composed of multi-layer materials. The upper and lower layers are high purity aluminum alloy plates, and the core layer is non-toxic and low-density polyethylene (PE) plate. And there is a protective film on the surface of the panel. For outdoor use, the aluminum composite panel will be painted with fluorocarbon resin (PVDF) coating; for indoor use, the coating can be non-fluorocarbon resin.The aluminum composite panel is a great material which is easy to process and mold. It is an ideal product for improving efficiency and saving working time, as well as shortening the construction period and reducing the cost. The aluminum composite panel can be cut, grooved, cut by band saw, drilled, processed, cold bent, cold folded, cold rolled, and can be riveted, screwed or glued and jointed.As a kind of high-tech composite materials, the aluminum composite panel has a history of more than thirty years since it is researched and developed in the 1960s. And its performance has been constantly improved and enhanced since it was developed. Nowadays it is widely applied in the transportation industry, construction industry and some special industries, such as the advertising industry, etc. In the construction industry, especially, it is commonly used because of its lightweight, relatively high relative strength, easy processing, and installation. It can be seen in the places which range from architectural interior to the exterior decoration, the lower buildings to the high-rise buildings.

Localisation : No.638, Qianxi Industrial Area, Wucheng District, Jinhua City, China , 321000 Jinhua,

Personne à contacter : Nelson Nee, +86 0579 15257918256