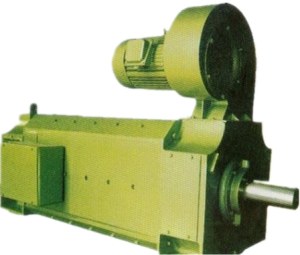

Description and Application

ZFQZ series DC motors are developed on the basis of Z4 series and ZZJ-800 series dc motor. The rotating inertia of the motor is 45% and 65% of the motors of series ZZJ-800 and ZZJ-900 respectively. The motors are suitable for direct and reversal rotation and start and stop in high frequency in a bad working circumstance. The motors are good-overloading. The maximum rotating moment and the starting moment are 112% and 117% of the moments of series ZZJ-800 motors. Respectively, the weight of the motor is just 65% of the series of ZZJ-800 dc motors. The class of the motor power is in accordance with the international standard, except for the axial distance between the mounting holes(dimension B). The mounting dimension of the motors with bottom plates is able to be in compliance with the dimension of series ZZJ-800 and ZZJ-900 series dc motor. Also, the shaft extension dimension of the motors can be customized into the corresponding dimension of series ZZJ-800 motors after discussion with customers. Therefore, ZFQZ series DC motor can instead for ZZJ-800 series motor.

Electrical Performance

1. There are 2 kinds of rated voltage of motors: 220V & 440V. As customer's requirement, the motors with other voltage can be produced.

2. The mode of excitation of motors is separate excitation. The standard excitation voltage is 180V. As customer's requirement, the motors with other voltage can be produced.

3. The motors running at basic speed can reach Max rotating moment regulated in the technical data

4. For the motors of rated voltage 220V, the rotating speed can reach as 2 times as the rated rotating speed through increasing the applied voltage. At this time, the allowable max. Rotating moment is as 1.8 times as the rated rotating moment.

5. For the motors of rated voltage 220V, the max. Rotating moment is as 0.6 times as the rated rotating moment when the motors are running with low-intensity magnetic rotation regulated in the technical data table.

6. The electric current changing rate of the motors can reach as 200-250 times as the rated electric current changing rate.

7. The standard position of wire outlet box of the motors is on the right of the machine baseplate seen from the drive end. If required, it can be mounted on the left of the machine baseplate. If so, this requirement should be stated in the order.

Structure:

1. The motor baseplate is of octagon laminated thin steel plate structure. Therefore, it has many advantage such as high utilization of stator room., tight inner structure, small rotating inertia, slight weight and suitability for supplying electricity by controllable silicon.

2. All the motors have compensating winding, which make motor have a good ability of commutation and overload.

3. The insulation level of motor is F class. The insulation of motors is handled by VPI. The winding has a good insulation and mechanical intensity.

4. The commutator segment is of vertical plate and integral structure. The connection with the vertical plate and armature coil adopts TIG.

5. The armature core is of skewed slot structure, which is able to decrease vibration and noise.

6. The motors are of rolling bearing and oil filling without stopping motors structure.

Order Notice:

According to customer's requirement, thsi series dc motor can be supplied together with techo generator, overspeed protective device, heater, temperature detecting and limiting elements, etc.

Localisation : 2# Canal Bridge Industry Park, Baoying Country, Jiangsu, China, 225825 Yangzhou,

Personne à contacter : Kyle Zhang, 86 29 89373928